Case Studies

Real-world examples of how we help clients bring products from concept to reality

Consumer Gadget Startup

Challenge

A hardware startup needed to transform their concept sketch into a manufacturable product for crowdfunding.

Approach

We provided full CAD modeling, DFM consulting, and rapid prototyping services. Multiple iterations refined the design for injection molding.

Deliverables

Production-ready CAD files, technical drawings, 5 functional prototypes, supplier RFQ package

Outcome

Successfully launched on Kickstarter with 300% funding. Product now in mass production.

Medical Device Component

Challenge

A medical device company required a custom enclosure that met strict regulatory requirements and tight tolerances.

Approach

Conducted thorough DFM analysis, materials selection for biocompatibility, and tolerance stack-up studies. Delivered SLA prototypes for testing.

Deliverables

FDA-compliant design documentation, biocompatible material specifications, 10 test prototypes

Outcome

Component passed all regulatory testing on first submission. Now in clinical trials.

Industrial Tool Redesign

Challenge

An existing tool needed ergonomic improvements and cost reduction for higher-volume production.

Approach

Reverse-engineered the existing design, conducted user testing, and optimized for manufacturing with fewer parts and simpler assembly.

Deliverables

Redesigned CAD models, ergonomic analysis report, cost comparison, 3 prototype iterations

Outcome

35% cost reduction per unit, improved user satisfaction scores, and faster assembly time.

IoT Sensor Housing

Challenge

A tech startup needed weatherproof housings for outdoor IoT sensors with specific mounting requirements.

Approach

Designed IP67-rated enclosures with integrated mounting systems. Prototyped with SLA for fit testing, then produced 50 units via CNC machining.

Deliverables

Weatherproof housing design, gasket specifications, mounting hardware, 50-unit production run

Outcome

Sensors deployed successfully in field testing. Client ordered additional 200 units for pilot program.

Custom Packaging Solution

Challenge

A boutique brand needed premium packaging that protected delicate products while maintaining brand aesthetics.

Approach

Designed custom inserts and structural packaging using sustainable materials. Prototyped with 3D printing and cardboard mockups.

Deliverables

Packaging design files, die-cut templates, material specifications, 100-unit small batch

Outcome

Packaging reduced damage rates by 80% and received positive customer feedback on unboxing experience.

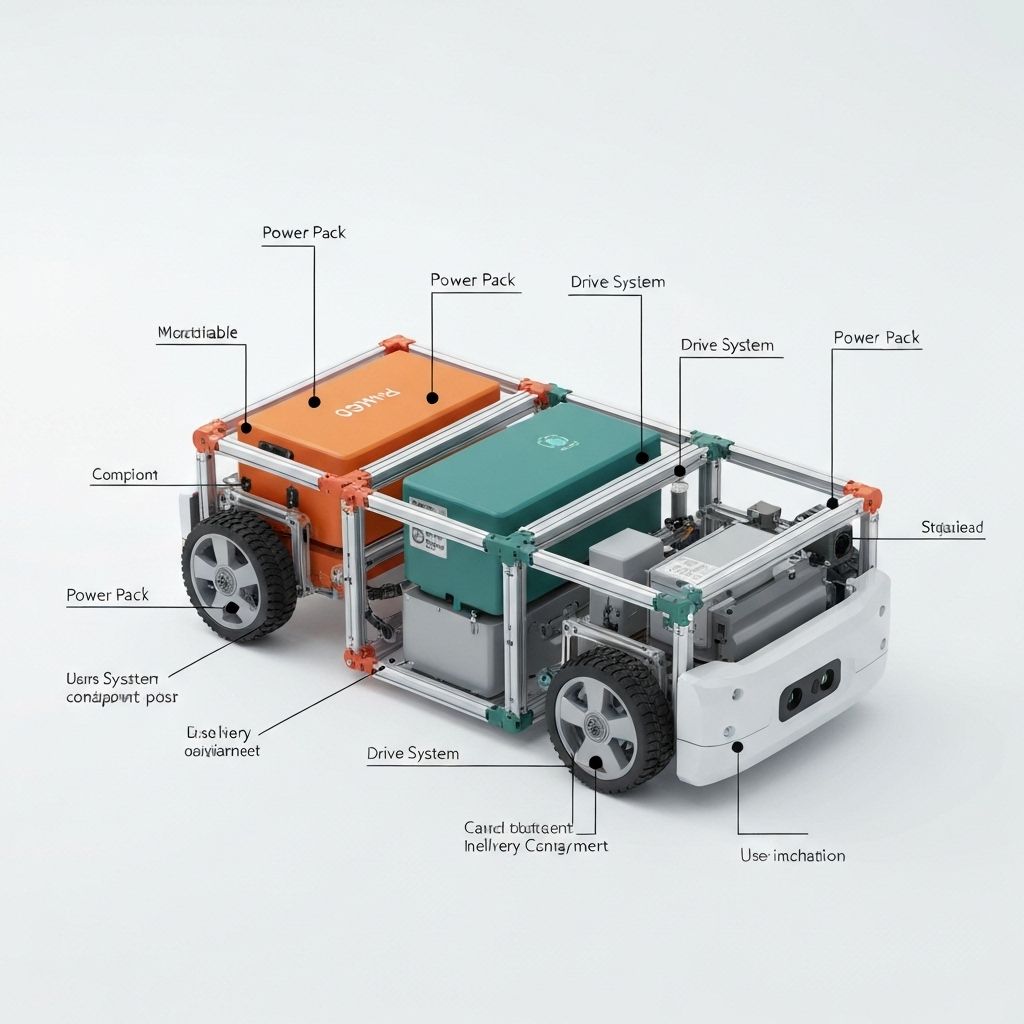

Autonomous Robotics Platform

Challenge

A robotics startup needed a modular chassis design for their autonomous delivery robot that could accommodate different payload configurations.

Approach

Developed a parametric CAD system allowing quick reconfiguration. Conducted FEA analysis for structural integrity and created multiple prototypes using SLS 3D printing for field testing.

Deliverables

Modular CAD assembly, FEA reports, 8 functional prototypes, assembly instructions, BOM with supplier recommendations

Outcome

Platform successfully tested in 3 cities. Design flexibility reduced time-to-market for new variants by 60%.

Aerospace Drone Component

Challenge

An aerospace company required lightweight, high-strength mounting brackets for commercial drone systems with strict weight and vibration requirements.

Approach

Utilized topology optimization and generative design techniques. Selected aerospace-grade aluminum alloy and validated designs through vibration testing and thermal analysis.

Deliverables

Optimized CAD models, material certifications, vibration test reports, 15 CNC-machined prototypes, production drawings

Outcome

Components achieved 40% weight reduction while exceeding strength requirements. Now standard in client's product line.

Start Your Project

Ready to bring your product idea to life? Request a quote or schedule a consultation.